As a soybean oil press operator, you're always looking for ways to boost oil extraction efficiency and extend the lifespan of your equipment. One of the most effective ways to achieve this is by properly maintaining the screw shaft and pressing chamber of your soybean oil press. These two components are crucial for the smooth operation of the oil press, and neglecting their maintenance can lead to a range of issues, from reduced oil quality to costly breakdowns.

Regular maintenance of the screw shaft and pressing chamber can significantly improve the performance of your soybean oil press. For example, studies have shown that weekly maintenance can extend the equipment's lifespan by up to 20%. Moreover, well - maintained components ensure a more consistent and higher - quality oil output. A clean and properly lubricated screw shaft and pressing chamber reduce friction, which in turn lowers energy consumption and increases the overall efficiency of the oil extraction process.

After each use, it's essential to clean the residues from the screw shaft and pressing chamber. Residual oil, soybean particles, and other debris can accumulate over time, leading to blockages and reduced efficiency. Use a soft brush and a suitable cleaning agent to gently remove the residues. This simple step can prevent many common problems and keep your oil press running smoothly.

Regularly inspect the screw shaft and pressing chamber for signs of wear. Look for any visible scratches, dents, or uneven surfaces. Excessive wear can affect the pressure distribution during the oil extraction process, resulting in lower oil yields. If you notice significant wear, it may be necessary to replace the parts to maintain optimal performance.

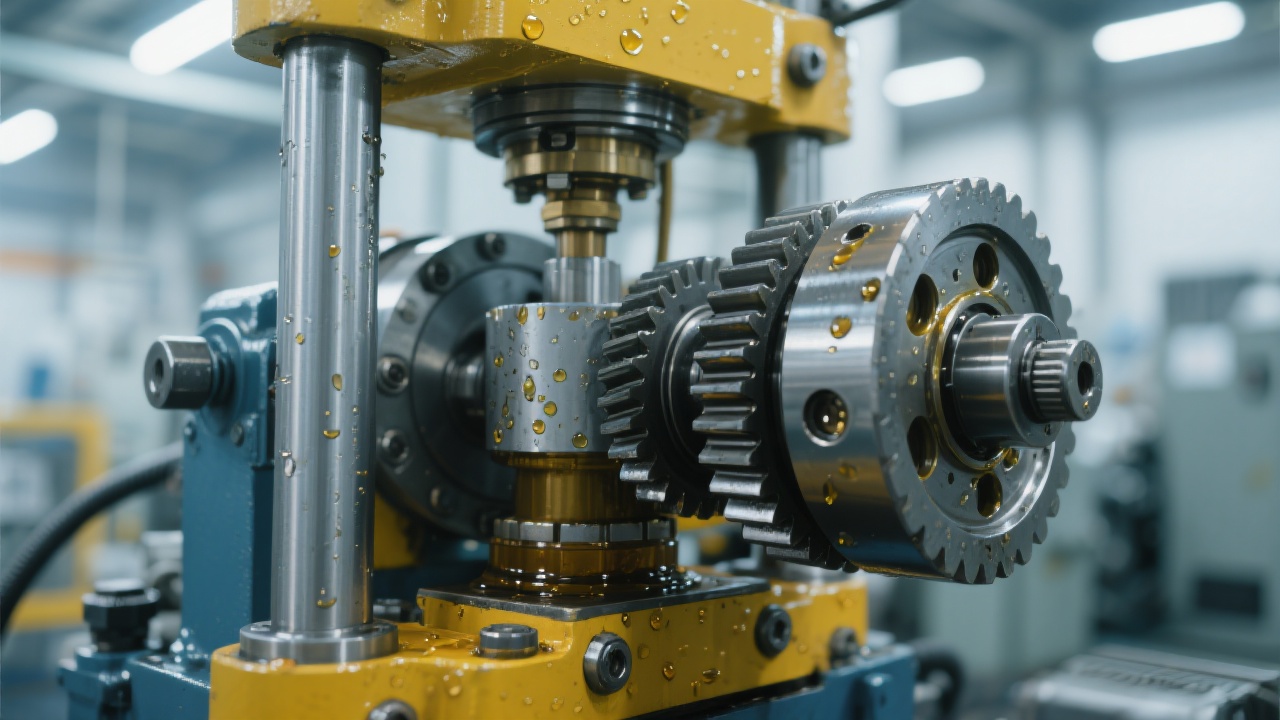

Lubrication is key to reducing friction and preventing premature wear. Use a high - quality lubricant recommended by the equipment manufacturer. Apply the lubricant to the appropriate parts of the screw shaft and pressing chamber according to the specified intervals. Over - lubrication can also cause problems, so follow the guidelines carefully.

The seals in the pressing chamber prevent oil leakage and ensure proper pressure build - up. Check the seals regularly for any signs of damage or deterioration. Replace any worn - out seals promptly to avoid oil loss and maintain the efficiency of the oil press.

Unusual noises from the oil press can indicate potential problems. If you hear any rattling, grinding, or other abnormal sounds, stop the machine immediately and investigate the cause. It could be due to loose parts, misalignment, or excessive wear. Addressing these issues early can prevent more serious damage.

Let's take a look at some common problems and their solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Cloudy oil | Residues in the pressing chamber | Clean the pressing chamber thoroughly |

| Reduced oil output | Worn screw shaft or blockage | Check and replace the screw shaft if necessary, clean the chamber |

| Abnormal noise | Loose parts or misalignment | Tighten loose parts and realign the components |

To make maintenance easier and more effective, we recommend using a regular maintenance checklist and an operation record template. These tools can help you keep track of maintenance tasks, identify patterns, and ensure that all necessary steps are taken. For example, you can create a weekly maintenance schedule and record the results of each inspection.

If you're looking for even more efficient and intelligent oil extraction solutions, our company offers a range of advanced soybean oil presses. These machines are designed with the latest technology to provide higher oil yields, better quality control, and easier maintenance.