As a professional in the global trade of oil processing equipment, I understand your concerns about the purity of oil products. In today's market, especially for export - oriented oil production, the purity of oil is a key factor that directly affects the competitiveness of your products. This article will take you through the application and maintenance of integrated oil filtering systems in soybean oil presses, aiming to help you produce high - quality export - grade oil.

The integrated oil filtering system has revolutionized the oil production process. Compared with traditional step - by - step filtering methods, it significantly improves efficiency. For example, in a traditional filtering process, the impurity content in the oil might be around 2 - 3%. After using an integrated oil filtering system, the impurity content can be reduced to less than 0.5%, a decrease of more than 75%. This not only improves the purity of the oil but also reduces the cost of subsequent refining.

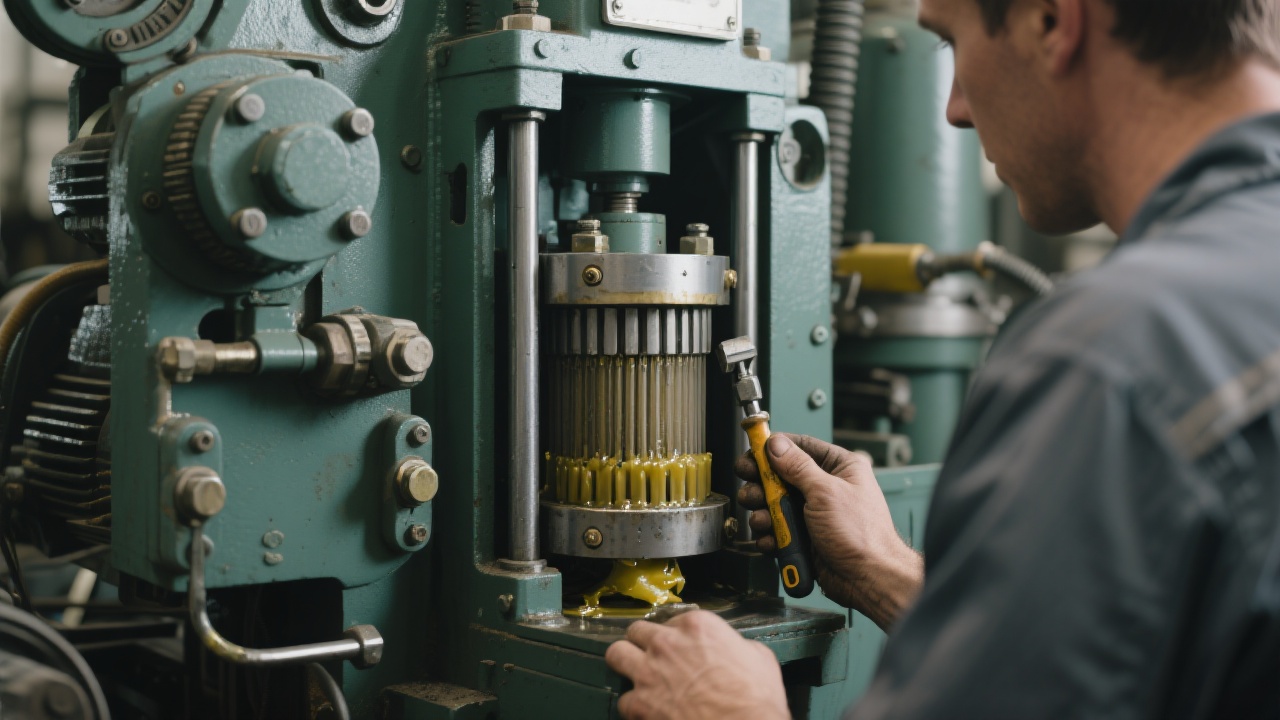

There are two main types of oil presses in the market: screw oil presses and hydraulic oil presses. Each has its own characteristics in terms of filtering technology.

| Oil Press Type | Filtering Technology Features | Suitability |

|---|---|---|

| Screw Oil Press | It has a continuous pressing process. The integrated filtering system can be directly installed at the oil outlet, achieving real - time filtering. The filtering efficiency is high, and it is suitable for large - scale continuous production. | Large - scale oil processing enterprises |

| Hydraulic Oil Press | It has an intermittent pressing process. The filtering system is usually integrated into the pressing chamber, which can ensure the purity of the oil during the pressing process. It is more flexible and suitable for small - and medium - scale production with different oil types. | Small - and medium - sized oil processing enterprises |

Proper maintenance of the oil filtering system is crucial to ensure its long - term stable operation. Here are some practical maintenance suggestions:

Many oil processing enterprises have achieved significant benefits through the upgrade of oil filtering systems. For example, a medium - sized oil processing enterprise in South America upgraded its screw oil press with an integrated oil filtering system. After the upgrade, the oil purity increased by 20%, and the production efficiency increased by 15%. At the same time, the cost of subsequent refining was reduced by 30%. This not only improved the quality of the products but also increased the enterprise's profit margin.

"After using the integrated oil filtering system, our oil products have won more orders in the international market. The improvement in oil purity has made our products more competitive." - A customer from an oil processing enterprise

The oil processing industry is gradually shifting from simply pursuing high production volume to focusing on oil purity and cost control in subsequent refining. As an oil processing enterprise, you need to adapt to this trend and choose the right oil press and filtering system to meet market demand.

In conclusion, the integrated oil filtering system plays a vital role in improving the purity of oil in soybean oil presses. By understanding the differences in filtering technologies between different types of oil presses and mastering the maintenance skills of the filtering system, you can ensure the stable quality of your export - grade oil. Click here to get the PDF of The Self - Inspection List for Oil Filtering Systems in Oil Presses, which will help you easily ensure the purity of exported oil.