High-Efficiency Soya Oil Making Machine for Optimal Oil Extraction

2025-02-25

Qi'e Grain and Oil Machinery Co., Ltd.

Case study

Discover our advanced soya oil making machine designed for efficient soybean oil extraction. With options for mechanical pressing and solvent extraction, our equipment maximizes yield and quality. Ideal for both small-scale and large-scale production.

Introduction to Soya Oil Making Machines

As a leading expert in the field, I have witnessed first-hand the remarkable advancements in oil extraction technology. The soya oil making machine stands out, specifically engineered to extract oil from soybeans through either mechanical pressing or solvent extraction methods. This versatility allows it to cater to both small-scale and large-scale production requirements.

Types of Soya Oil Making Machines

1. Mechanical Pressing Machine

The mechanical pressing machine utilizes a screw press, efficiently squeezing oil from soybeans. This method typically yields between 70-80% of the oil content, making it an excellent choice for small to medium-sized operations.

2. Solvent Extraction Machine

For large-scale production, the solvent extraction machine proves to be indispensable. It employs a solvent, typically hexane, to dissolve the oil from the remnants after pressing, achieving an impressive yield of nearly 99%.

3. Combined Pressing and Solvent Extraction Machine

To maximize efficiency, some machines integrate both mechanical pressing and solvent extraction. This combination ensures optimal oil recovery, catering to varying production demands.

How Does a Soya Oil Making Machine Work?

The oil extraction process involves several crucial steps:

- Soybean Cleaning: Raw soybeans undergo initial cleaning to eliminate impurities, including dirt and metal objects.

- Crushing and Flaking: The cleaned soybeans are crushed and flaked to enhance surface area for efficient extraction.

- Conditioning: The flakes are heated to soften the material, preparing it for extraction.

- Oil Extraction: The oil is extracted either mechanically or through solvents based on the selected machine.

- Filtering and Refining: Post-extraction, the oil is filtered to remove impurities, followed by potential refining.

- Packaging: Finally, the refined oil is packaged for distribution.

Benefits of Using a Soya Oil Making Machine

- High Oil Yield: Achieving up to 99% oil extraction ensures minimal waste and heightened efficiency.

- Cost-Effective Production: Modern machinery automates much of the extraction, significantly reducing labor costs.

- Versatility: These machines are effective for various oilseeds, including sunflower and sesame, enhancing operational flexibility.

- Sustainability: Efficient extraction minimizes waste, producing by-products like soybean meal for animal feed.

- Scalability: A range of sizes and configurations aligns with both small endeavors and large industrial setups.

Choosing the Right Soya Oil Making Machine

When selecting a machine, consider the following factors:

- Capacity: Determine your daily processing requirements and choose a machine accordingly.

- Efficiency: Look for machines with high extraction rates, ensuring maximum yield.

- Automation Level: Fully automated options may enhance efficiency, whereas semi-automatic ones can be more budget-friendly.

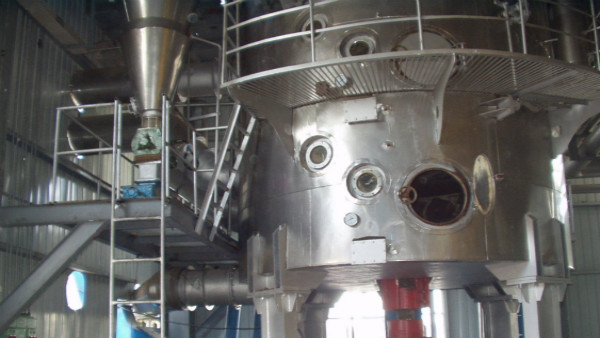

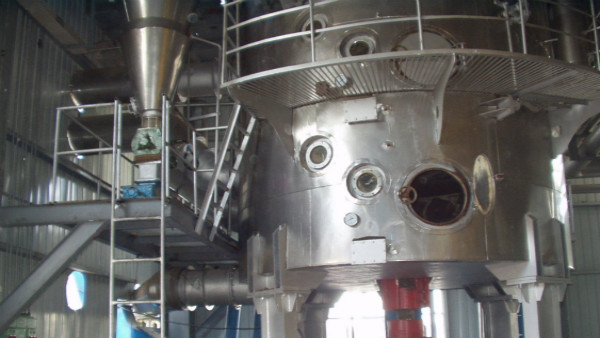

- Durability and Quality: Opt for stainless steel machines for longevity and reduced maintenance.

- Supplier Reputation: Purchase from established manufacturers with reliable support and service.

Conclusion

Investing in a soya oil making machine is a strategic choice for anyone entering the lucrative oil production sector. By evaluating various machines based on your production needs and collaborating with reputable suppliers, you can ensure maximum efficiency and quality in your operations.