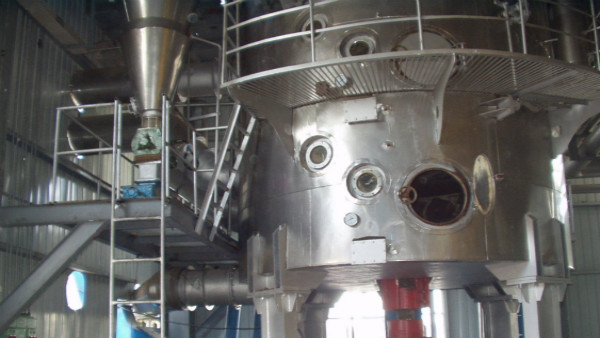

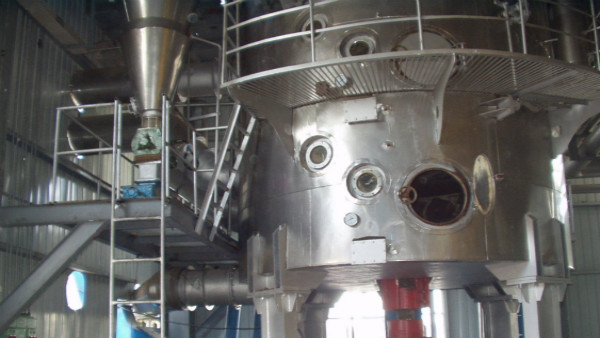

High-Efficiency Soya Oil Making Machines for Optimal Soybean Oil Production

2025-02-17

Qi'e Grain and Oil Machinery Co., Ltd.

Product description

Discover the advanced soya oil making machines designed for high oil yield and efficiency in soybean oil production. Explore mechanical pressing, solvent extraction, and combined methods suited for various scales of production.

Understanding the Requirements of Oil Production

In the evolving edible oil market, producers face a growing need for high-efficiency oil extraction solutions. As demand for soybean oil continues to rise, the challenge remains: how can producers maximize yield while minimizing operational costs? This article discusses the various types of soya oil making machines and offers insights into making informed purchasing decisions.

Types of Soya Oil Making Machines

1. Mechanical Pressing Machine

Mechanical pressing machines utilize screw mechanisms to extract oil from soybeans. Ideal for small to medium operations, they yield approximately 70-80% of the oil content and provide a straightforward, cost-effective solution for oil production.

2. Solvent Extraction Machine

For large-scale production, solvent extraction machines are the preferred choice. Utilizing solvents such as hexane, these machines can recover up to 99% of the oil content, ensuring minimal waste and higher profit margins.

3. Combined Pressing and Solvent Extraction Machine

Some manufacturers opt for a hybrid solution that combines both mechanical pressing and solvent extraction methods. This maximizes oil recovery rates while enhancing overall efficiency.

How Does a Soya Oil Making Machine Work?

The extraction process comprises several crucial stages to ensure optimal output:

- Soybean Cleaning: Raw soybeans are cleaned to eliminate impurities.

- Crushing and Flaking: The beans are then crushed and flaked to enhance the extraction surface area.

- Conditioning: Flakes are heated to soften and prepare them for oil extraction.

- Oil Extraction: Oil extraction occurs via mechanical means or solvent application.

- Filtering and Refining: The crude oil is filtered and may be refined for enhanced quality.

- Packaging: The finished oil is packaged for distribution.

Benefits of Using a Soya Oil Making Machine

Investing in a soya oil making machine presents numerous advantages:

- High Oil Yield: Solvent extraction methods achieve an oil yield of up to 99%, maximizing profitability.

- Cost-Effective Production: Automation reduces labor costs, optimizing production output.

- Versatility: These machines can process various oilseeds, making them valuable additions.

- Sustainability: The extraction process generates by-products like soybean meal, which has numerous applications.

- Scalability: Machines are available in multiple sizes to accommodate different production scales.

Choosing the Right Soya Oil Making Machine

Selecting an appropriate machine involves careful consideration:

- Capacity: Identify a machine that meets your daily production requirements.

- Efficiency: Opt for high extraction rate machines to maximize yield.

- Automation Level: Fully automated machines reduce labor costs but may have a higher initial investment.

- Durability and Quality: Look for machines constructed from high-quality materials like stainless steel for longevity.

- Supplier Reputation: Purchase from trusted suppliers with a solid track record in machine reliability.

Conclusion

Investing in a high-efficiency soya oil making machine is an essential step for those entering the dynamic oil production industry. With the right machinery tailored to your needs, you can ensure effective, sustainable, and profitable operations. Exploring various options lets you maximize your production capability while delivering high-quality soya oil to the market.