If you’re seeking to enhance the quality of your soybean oil but feel uncertain about which pressing equipment matches your production goals, this article will be your essential guide. Hydraulic oil presses leveraging cold-pressing (cold pressing) technologies are becoming a cornerstone in producing high-end edible oils. By maintaining low temperature during extraction, these machines preserve the nutritional profile, flavor integrity, and clarity of soybean oil far better than conventional methods.

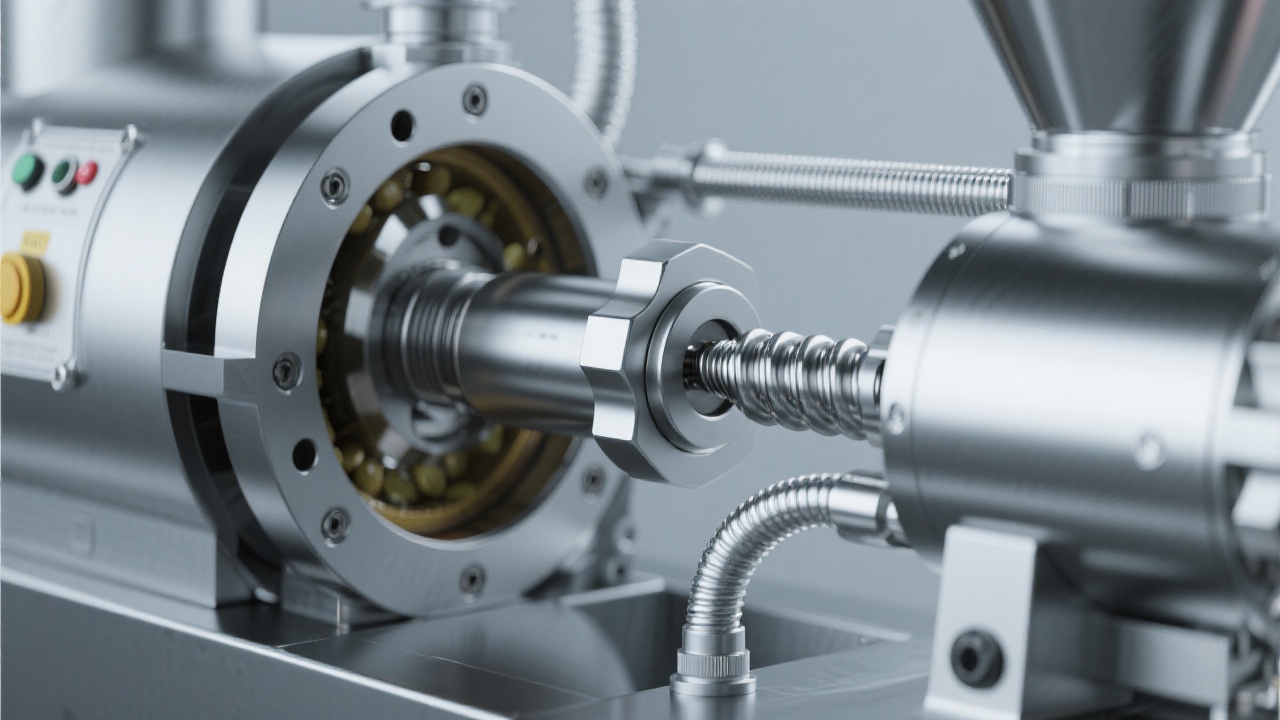

The core mechanism of hydraulic cold-pressing involves applying slow, high-pressure compression at temperatures typically under 50°C (122°F). This ensures the natural constituents of soybean oil—like Vitamin E, phospholipids, and essential fatty acids—are retained at significantly higher levels compared to mechanical screw pressing (hot pressing).

“Hydraulic cold-pressing can boost Vitamin E retention in soybean oil by approximately 15%, delivering a nutritionally superior product that captures consumer demand for health-conscious oils.” – Industry Expert Report, Global Edible Oils 2023

Thanks to the gentle yet effective hydraulic cold-pressing process, this technology suits multiple production scales:

| Feature | Hydraulic Cold-Press | Screw Press |

|---|---|---|

| Operating Temperature | Below 50°C (Cold) | Up to 120°C (Hot) |

| Nutrient Retention (e.g. Vitamin E) | ~15% Higher | Standard |

| Energy Consumption | Lower | Higher |

| Oil Yield Percentage | Slightly Lower (~3-5%) | Higher (Up to 95%) |

| Maintenance Complexity | Simpler, Less Wear | More Frequent & Intensive |

| Processing Speed | Slower (Quality Emphasis) | Faster (Volume Emphasis) |

Q1: Does cold-pressing mean lower productivity?

While hydraulic cold presses operate at a slower throughput compared to screw presses, the tradeoff is higher oil quality and nutrient retention. For producers targeting premium or organic markets, this productivity difference is often a worthwhile investment.

Q2: Is the cold-press process more energy costly?

On the contrary, cold-pressing typically consumes less energy since it avoids prolonged heating phases common in screw pressing, making it more sustainable and cost-effective in the long run.

Q3: How do I determine if hydraulic cold-pressing suits my needs?

Consider your production scale, oil quality targets, and budget constraints. Hydraulic cold-pressing is ideal if you prioritize nutritional integrity and natural flavor and are catering to niche or health-focused customer segments.

To assist you in pinpointing the optimal oil pressing solution, here’s a concise checklist:

If you can answer ‘yes’ to most of these, hydraulically driven cold-pressing technology is likely your best ally.