When it comes to selecting a soybean oil press for your manufacturing line, deciding between a spiral screw press and a hydraulic press can be challenging. Both technologies have distinct operational principles and are optimized for different production needs and oil quality standards. This guide walks you through a detailed comparison of these two machines, focusing on efficiency, oil quality, energy consumption, and maintenance costs, enabling you to confidently choose the ideal model for your production scale and business objectives.

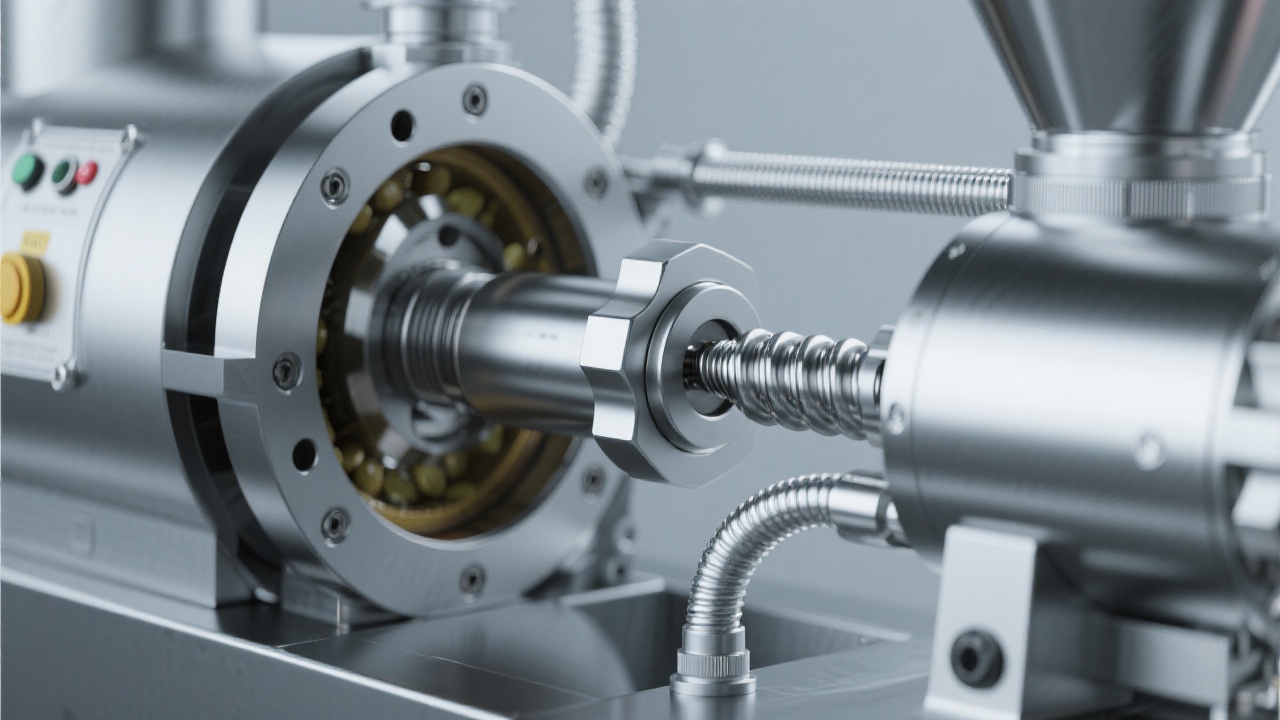

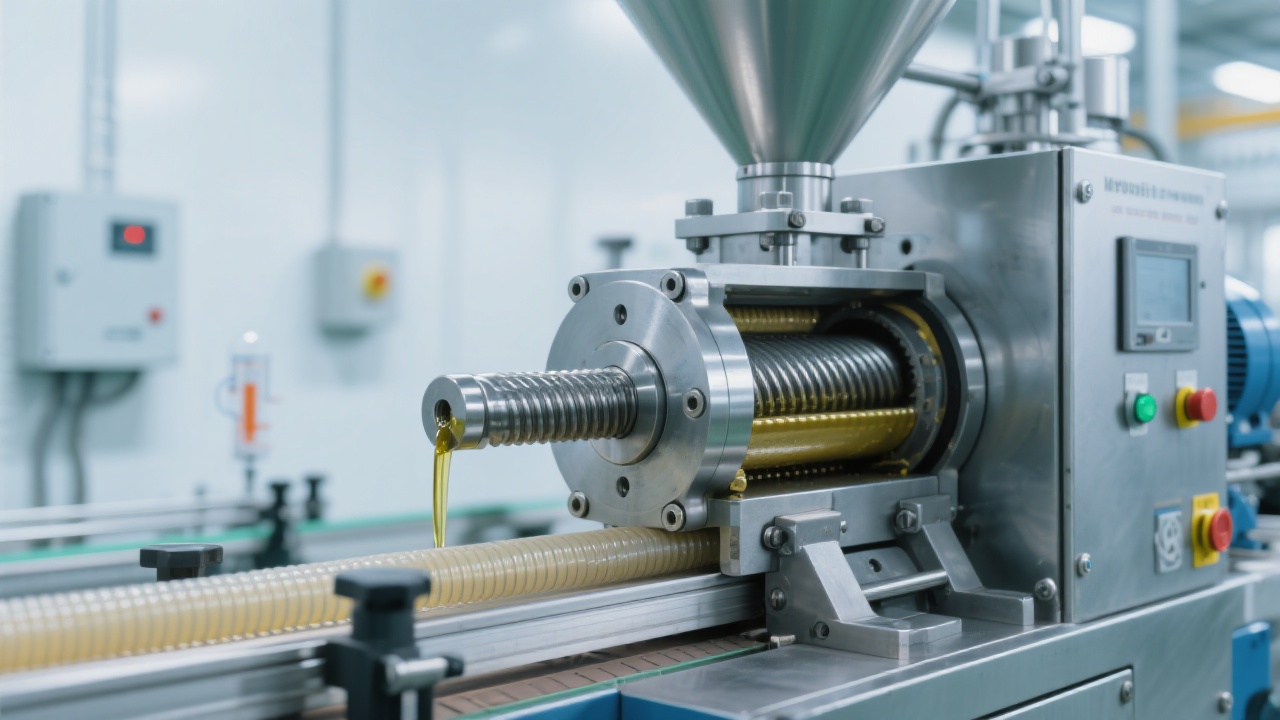

The spiral screw (extrusion) press operates via a continuous rotating screw that crushes soybeans at high speed, generating heat through friction which partially cooks the material, thus increasing oil yield. In contrast, the hydraulic press uses mechanical pressure applied gradually by a hydraulic system, pressing the beans slowly to extract oil, which makes it especially suited for cold pressing to maintain raw material nutrients intact.

Key Technical contrast:

| Parameter | Spiral Screw Press | Hydraulic Press |

|---|---|---|

| Operation Mode | Continuous, high-speed screw rotation | Batch process with gradual hydraulic pressure |

| Oil Yield | Approx. 95%-98% | Approx. 85%-92% |

| Oil Quality | Higher temperature may degrade some nutrients | Cold pressing preserves nutrients and aroma |

| Energy Consumption | Higher due to motor power and heating | Lower, mainly hydraulic pumping |

| Suitable Scale | Medium to large industrial lines (500kg/hr+) | Small to medium-scale, artisanal cold pressing |

If your production line is intended for high-volume output—say, 1000 kg/hour or more—the spiral screw press is the clear choice. Its continuous operation and automation-friendly features result in a 30%-40% increased throughput compared to hydraulic presses of comparable size. Plus, modern spiral presses integrate automatic feeding and discharge functions, reducing labor costs.

A real-world case:

“Our mid-sized factory switched from a traditional hydraulic press to a spiral screw press and saw oil extraction rates jump from 90% to 97%, while cutting processing time by nearly half. Maintenance downtime dropped 20%, thanks to simpler mechanical parts.” – Golden Harvest Oils, China

On the other hand, if your priority is the production of premium cold-pressed soybean oil rich in natural flavors and bioactive compounds, the hydraulic press remains unrivaled. It operates at low temperatures (<45°C), minimizing nutrient loss and oxidation. This is crucial for health-focused niche markets demanding purity and authentic taste.

Regardless of the press type, incorporating an integrated oil filtration system can drastically improve oil clarity, shelf life, and consumer acceptance. Advanced filter presses remove fine particulates and impurities post-extraction, achieving oil purity levels exceeding 99%. Industry trends indicate growing adoption of these systems, aligning with stringent quality regulations in export markets.

Ask yourself these questions to pinpoint the right press equipment:

Recognizing where you stand on these criteria will help you navigate the trade-offs and choose equipment that adds the most value.

| Factor | Spiral Screw Press | Hydraulic Press |

|---|---|---|

| Production Scale | High (Industrial, 500kg+/h) | Low to Medium (Artisanal to 500kg/h) |

| Oil Quality | Good, moderate heat involved | Excellent, cold-pressed |

| Yield Efficiency | Higher (up to 98%) | Lower (85-92%) |

| Energy Use | Higher consumption | Lower consumption |

| Maintenance Complexity | Moderate, automated parts | Higher, manual operation |

Equipped with this comparative analysis, you are better positioned to decide which type of machine complements your production priorities. Whether you seek to maximize throughput with a spiral screw press or maintain premium, cold-pressed oil quality with a hydraulic press, selecting the right equipment is critical to your success in the competitive global soybean oil market.

Click to Discover How to Choose the Best Soybean Oil Press for Your Production Scale