In the competitive landscape of soybean oil extraction equipment, two primary technologies dominate the marketplace: the spiral (screw) oil press and the hydraulic oil press. Each machine offers distinct advantages influenced by factors such as production scale, oil quality preferences, operational efficiency, and investment budgets. This article provides a detailed comparison of these two types, empowering exporters and buyers to make informed procurement decisions aligned with their business needs.

The spiral oil press operates by continuously feeding soybeans through a rotating screw shaft inside a barrel. The friction and mechanical pressure exerted by the screw gradually crush and press the oil seeds, extracting oil at relatively high throughput rates. Typically, temperatures during the process rise slightly, classifying this as a hot-pressing method, but it can be adapted for cold pressing with controlled parameters.

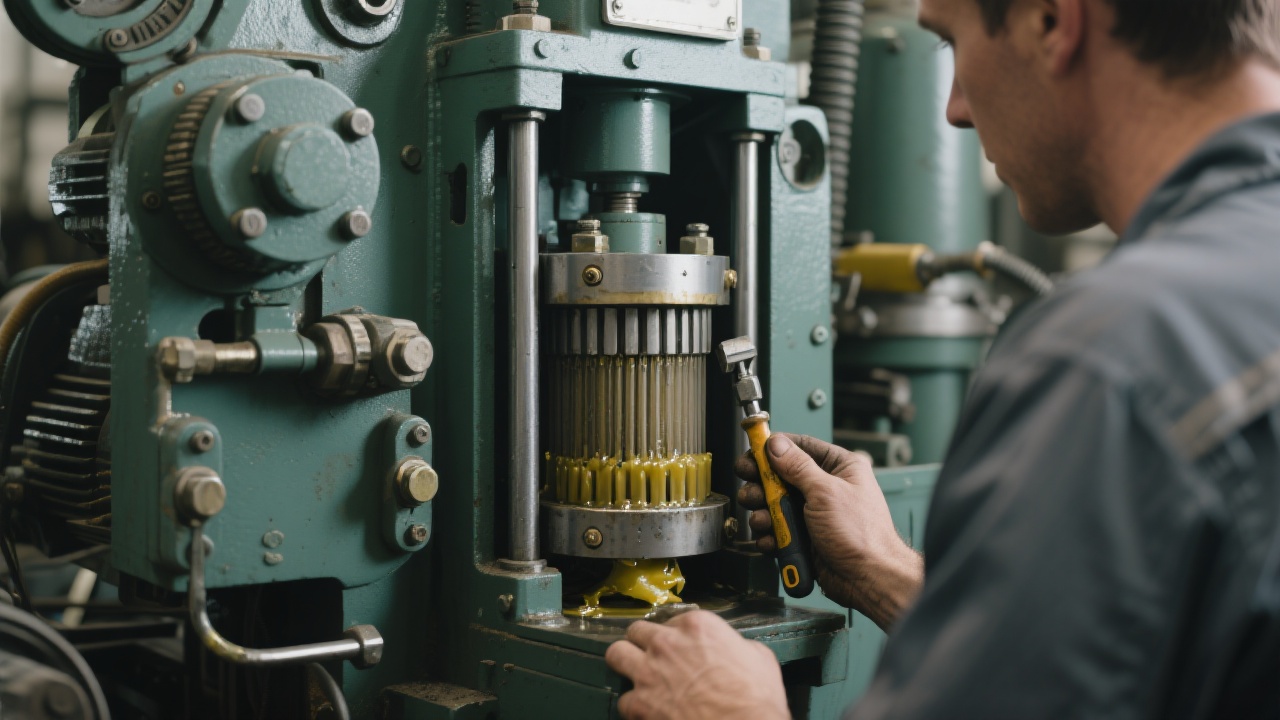

In contrast, the hydraulic oil press uses high-pressure hydraulic cylinders to apply slow and uniform pressing force on pre-treated soybeans, often in batches. This process maintains lower temperatures, preserving the oil's natural flavor and nutrients, ideal for cold-pressed oil production with premium quality requirements.

| Criteria | Spiral Oil Press | Hydraulic Oil Press |

|---|---|---|

| Oil Yield (%) | Approx. 18-20% | Higher, approx. 20-22% |

| Processing Speed | Up to 300 kg/hr | Slower, approx. 100-150 kg/hr |

| Oil Quality (Cold Pressed) | Moderate if temperature controlled | Excellent, retains flavor & nutrients |

| Maintenance Complexity | Moderate, moving parts require upkeep | Lower, simpler hydraulic system |

| Suitable Application | Large-scale commercial production | Small to medium batch premium oils |

For instance, a medium-sized soybean oil exporter in Brazil uses spiral oil presses with integrated production lines, achieving up to 10 tons daily with an output oil quality suitable for bulk commercial sales. The fast processing capability and scalability fit their high-volume demands.

Conversely, a boutique cold-pressed oil brand in the USA opts for hydraulic presses to market premium, nutrient-rich soybean oil with authentic flavor retention. Their batch-style processing and smaller scale prioritize oil quality and organic certification over speed.

Recent advances integrate filtering units directly with both spiral and hydraulic oil presses to enhance oil purity and clarity. Innovative filter systems can reduce residual particulates by over 25%, significantly improving oil shelf-life and customer satisfaction. These filters support quick separation of solid residues without using chemical additives, preserving natural oil composition.

Selecting between spiral and hydraulic soybean oil press machines is crucial in defining your production efficiency and oil quality. A clear understanding of your business objectives—whether prioritizing higher volume or superior oil purity—will guide you effectively.