For manufacturers and exporters relying on soybean oil presses, smooth and stable machine operation is paramount for maximizing yield and oil quality. This article dives deep into the core maintenance and operational practices focused on soybean cleaning and feeding, designed to minimize downtime and optimize extraction efficiency.

The first critical step in maintaining high-performance soy oil presses is thorough cleaning of soybeans before feeding. Foreign materials like stones, husks, and dirt not only cause feed blockages but also elevate wear on the screw shaft and other components. Industry best practice recommends a multi-stage cleaning process involving:

Note: Consistent monitoring of input material moisture under 12% prevents clogging and assures efficient pressing.

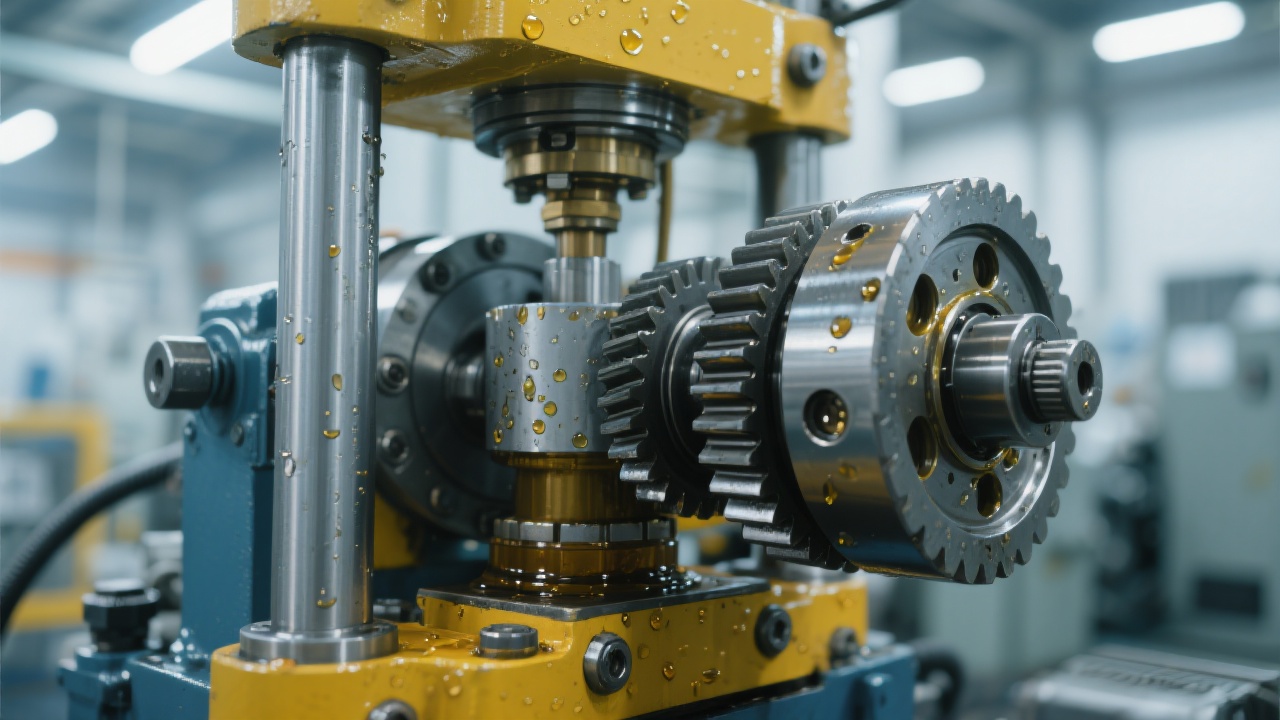

Frequent lubrication of the screw shaft and pressing chamber is essential to reduce mechanical friction and avoid heat build-up that can degrade oil quality. A recommended maintenance schedule involves:

| Component | Lubrication Frequency | Recommended Lubricant |

|---|---|---|

| Screw Shaft Bearings | Every 8 hours of operation | High-temperature grease (NLGI Grade 2) |

| Pressing Chamber Walls | Daily inspection; apply light oil as needed | Food-grade mineral oil |

Regular lubrication minimizes machine vibration and abnormal noises, two common signs of wear that directly impact press efficiency.

Oil filtration systems play a vital role in removing impurities and safeguarding final oil quality. Accumulated residues in filters reduce throughput and increase oil turbidity. Cleaning protocols include:

Such routine maintenance guarantees consistent oil clarity and extends filter life, reducing overall operational costs.

a) Declining Oil Yield: Often arises from dirty feedstock or worn pressing components. A quick check on feed cleanliness combined with screw shaft wear inspection can identify the root cause.

b) Increased Oil Impurities: Usually linked to clogged or damaged filtration units. Immediate cleaning or replacement is critical.

c) Unusual Machine Noise: May indicate insufficient lubrication or bearing damage. Early diagnosis through vibration analysis can prevent catastrophic failures.

Action Tip: Maintain a daily log of operating parameters and anomalies to enable predictive maintenance and root cause traceability.

Transitioning from reactive repairs to preventive maintenance improves machine uptime and ROI. A comprehensive routine should include:

Empowering operators with clear SOPs and training enhances consistency and reduces user error-related downtime.

Mastering soybean cleaning and feeding techniques, paired with diligent maintenance and troubleshooting, establishes a robust foundation for stable and efficient oil pressing operations. This technical know-how reduces costs caused by downtime and oil quality degradation, directly boosting your profitability in competitive export markets.

For businesses aiming to elevate production reliability and oil quality, learning from proven case studies and adopting scientifically validated procedures is indispensable. Integrate these practices to sustain long-term growth and reinforce customer confidence worldwide.