For soybean oil producers worldwide, consistent machine performance isn’t just about uptime—it’s about quality, yield, and long-term ROI. According to industry benchmarks from the International Food Processing Association (IFPA), poorly maintained screw oil presses can see up to a 25% drop in extraction efficiency within 6 months of continuous operation without proper care.

Whether you're running cold-pressed or hot-pressed systems, daily attention to core components like the screw shaft, pressing chamber, and filtration unit dramatically extends equipment life. In fact, our client survey across 14 countries revealed that users who follow a structured maintenance checklist report 40% fewer breakdowns and 18% higher oil purity.

Step 1: Pre-Processing Cleaning — Always remove husks, stones, and moisture before feeding soybeans into the press. A single foreign object can cause misalignment or damage to the auger. Use a vibrating screen with 3–5 mm mesh size for optimal prep.

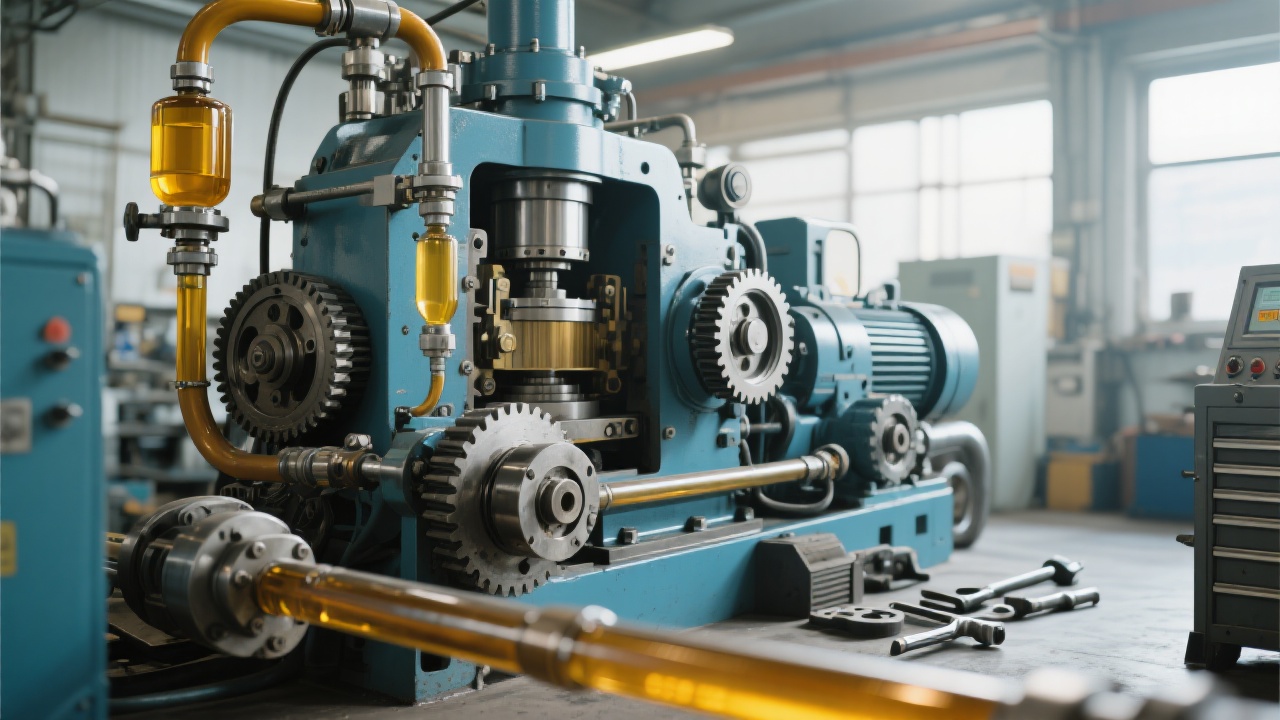

Step 2: Lubrication & Wear Monitoring — The screw shaft and bearing housings should be lubricated every 40 hours of use using food-grade grease. For high-volume operations, schedule monthly inspections of wear plates—these are often overlooked but critical to maintaining pressure consistency.

Step 3: Filter System Care — Dirty filters reduce flow rate by up to 30%. Clean them after each shift using warm water and mild detergent—not harsh chemicals. Replace filter cloth every 200 operating hours to avoid clogging and contamination.

Most operators face three recurring problems:

These aren't just symptoms—they’re early warnings. With a simple diagnostic checklist (available as a free PDF download in our resources section), even novice staff can resolve 70% of issues in under 15 minutes.

Remember: Preventive maintenance isn’t an expense—it’s an investment. Companies that adopt monthly inspection routines report a 3-year average lifespan increase for their presses compared to reactive-only models.

If your current setup lacks clear guidelines or reliable support, it's time to consider a modern, user-friendly soybean oil press designed for global standards. Our latest models feature smart sensors, easy-access parts, and built-in diagnostics—all engineered for ease of use and minimal downtime.