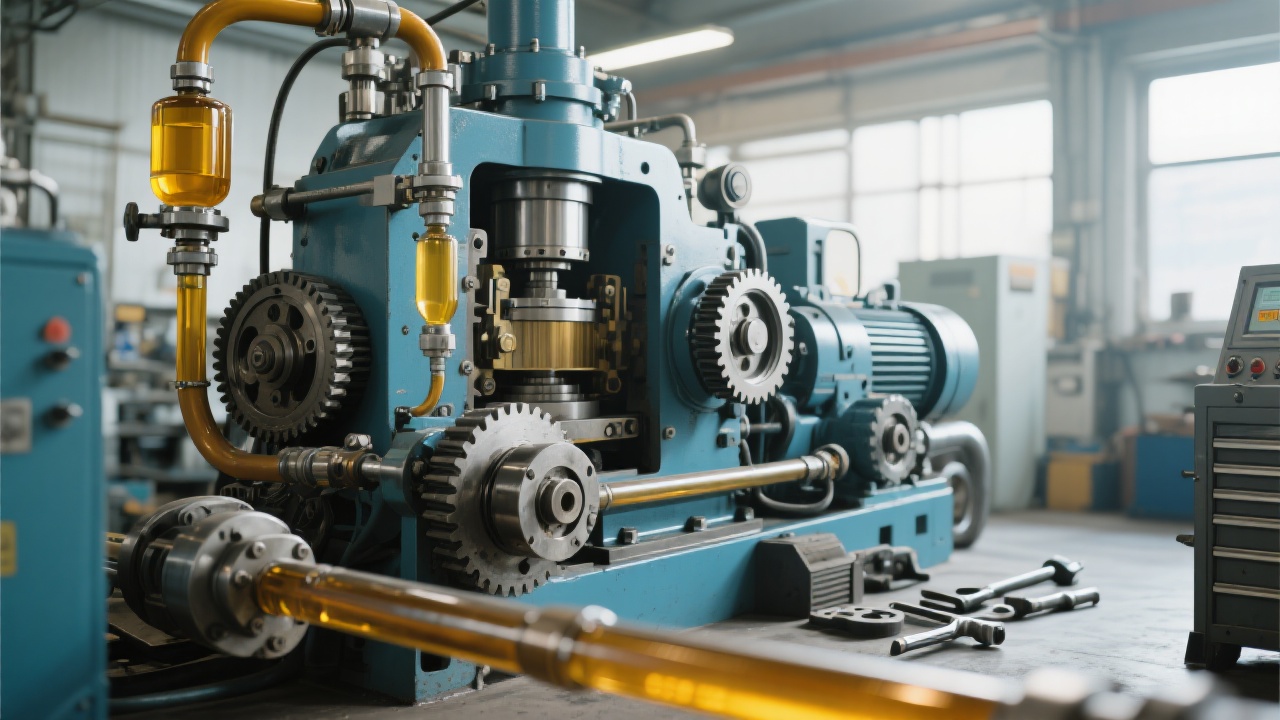

Running a soybean oil press machine smoothly requires more than just power— it demands proper operation and consistent maintenance. By mastering key operational techniques and maintenance routines, you can significantly enhance your machine's efficiency, extend its service life, and ensure superior oil quality. This guide walks you through the essential steps—from soybean preparation to troubleshooting common issues—equipping you with actionable tips for optimized performance.

Before starting the pressing process, ensure the soybeans are thoroughly cleaned. Remove foreign materials such as stones, dust, and plant residues to avoid machine damage or contamination. Clean soybeans improve pressing efficiency by up to 15% and reduce wear on internal components.

Recommended steps:

Proper feeding is crucial. Check the hopper and feed chute for obstructions or buildup. A smooth feed ensures consistent material flow, preventing pressure fluctuations or stoppages that could reduce output by up to 20%.

Maintenance tips:

The screw shaft and pressing chamber are wear-prone areas requiring consistent attention:

| Maintenance Step | Frequency | Key Points |

|---|---|---|

| Visual inspection for wear and corrosion | Weekly | Replace worn screws before performance drops |

| Lubricate bearings and shaft seals | Bi-weekly | Use recommended grade lubricants to minimize friction |

| Clean pressing chamber to prevent residue buildup | Monthly | Disassemble carefully to avoid component damage |

Maintaining the filtration system is key to delivering pure oil and ensuring continuous operation. Clogged or dirty filters can lower oil clarity by up to 25% and increase downtime.

Follow these steps for effective cleaning:

| Issue | Cause | Solution |

|---|---|---|

| Decline in Oil Yield | Blocked feed or worn screw shaft | Clean feed channel; replace or refurbish screw |

| Increased Oil Impurities | Dirty filtration or contaminated raw material | Clean filters; use properly cleaned soybeans |

| Abnormal Noise from Machine | Bearing wear or lubrication failure | Inspect and replace bearings; apply lubricants |

Beyond reactive repairs, adopting a preventive maintenance schedule can save you significant operational costs and downtime.

Key recommendations include: