Choosing the right oil press is one of the most critical decisions for any soybean processing facility—whether you're running a small-scale operation or managing a large industrial plant. The wrong choice can lead to wasted energy, inconsistent oil quality, and poor return on investment. In this guide, we’ll break down the key differences between screw presses and hydraulic presses, compare their performance across real-world metrics, and help you make an informed decision based on your specific needs.

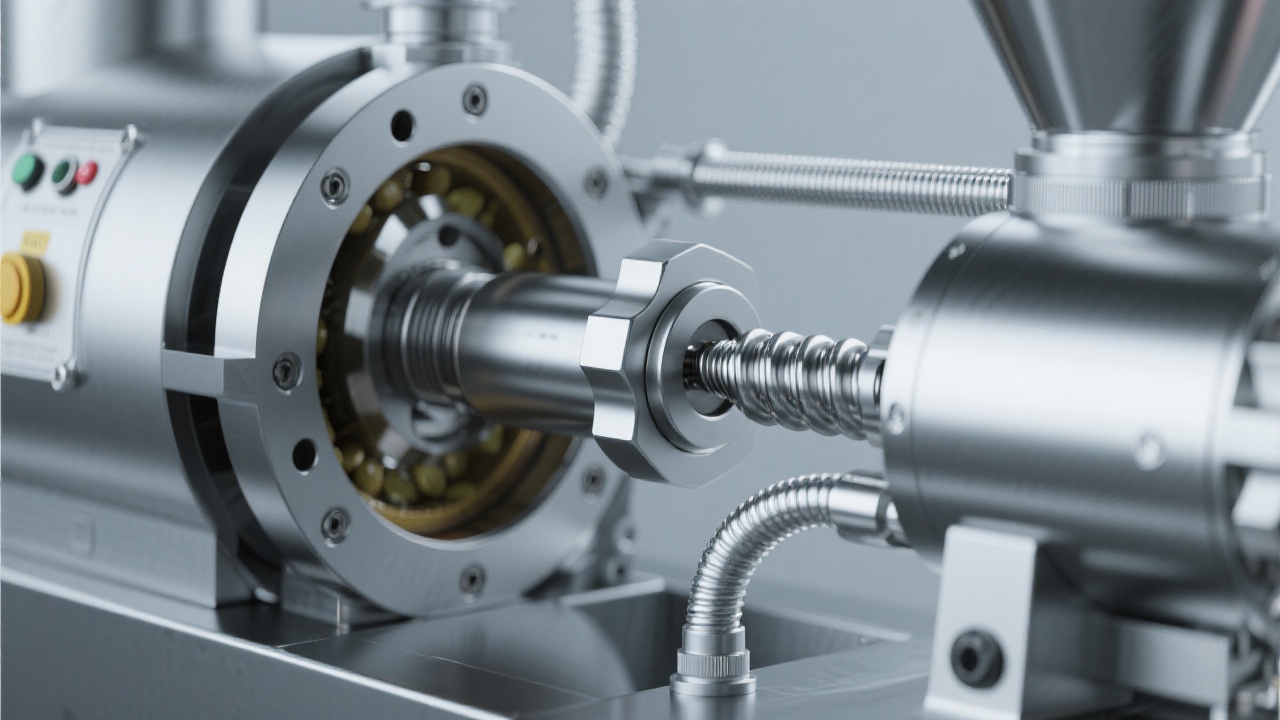

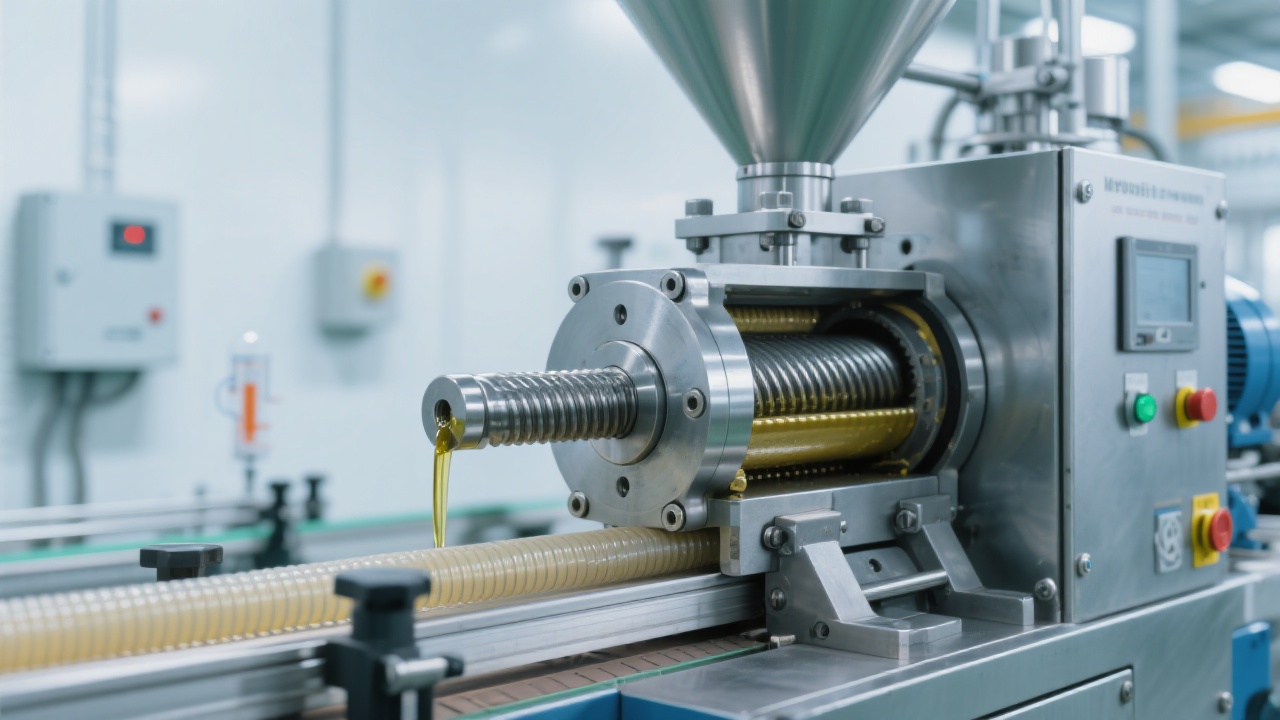

Think of a screw press as a continuous conveyor belt that squeezes oil out of soybeans through mechanical pressure. It’s like squeezing juice from oranges using a citrus press—you keep feeding in material and get steady output. A hydraulic press, meanwhile, applies high-pressure force in short bursts—similar to how a car jack works—making it ideal for cold-pressing or low-volume operations where precision matters more than speed.

| Criteria | Screw Press | Hydraulic Press |

|---|---|---|

| Daily Capacity (kg) | 500–5,000 kg/day | 50–1,000 kg/day |

| Oil Yield (%) | 90–95% | 85–92% |

| Energy Consumption (kWh/kg) | 0.3–0.5 kWh/kg | 0.6–1.0 kWh/kg |

| Maintenance Frequency | Monthly | Weekly |

If you process over 2,000 kg of soybeans daily and prioritize consistent throughput, a screw press is likely your best bet—it offers higher efficiency, lower labor cost per ton, and better scalability. For smaller workshops (<500 kg/day), especially those aiming for premium cold-pressed oil, a hydraulic press gives superior control over temperature and pressure, leading to cleaner, more aromatic oil.

A family-run oil mill in Vietnam used a manual hydraulic press for years. Their yield was around 87%, with frequent downtime due to clogged filters. After switching to a semi-automatic screw press (capacity: 3,000 kg/day), they saw immediate improvements: oil yield rose to 93%, maintenance dropped by 40%, and customer complaints about cloudy oil vanished. They now serve three local restaurants and export to neighboring countries.

Modern presses often come with built-in filtration units that remove phospholipids and impurities during extraction—not just improving clarity but also extending shelf life and reducing downstream refining costs. If you plan to sell directly to consumers or food manufacturers, consider this feature as part of your selection criteria.

Take our 2-minute self-assessment: How much soybeans do you process daily? What’s your target oil quality? And what’s your budget range? Based on your answers, we’ll recommend the optimal press configuration—including optional upgrades like automatic controls or integrated filters.

Click here to get your custom soybean oil press recommendation