For global buyers and industry professionals, understanding the multi-step production process of soybean oil is essential for ensuring quality, compliance, and efficiency. Many buyers may not realize how each stage of the process contributes to higher yield, better quality, and adaptability to different market requirements. This article will walk you through the key steps in soybean oil production, backed by real-world data and examples, to help you make informed decisions.

Traditional soybean oil production often involves a single or limited number of steps, which can result in lower yields and inconsistent quality. In contrast, a multi-step approach ensures that every stage is optimized for maximum output and purity. For example, a well-structured production line can achieve an oil extraction rate of up to 92%, compared to around 85% with less advanced methods.

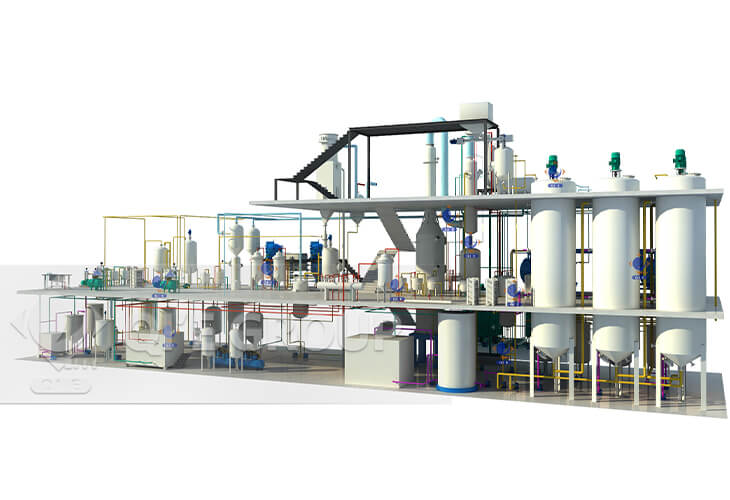

The multi-step process includes several critical stages, each playing a unique role in the final product’s quality and quantity:

The first step is to clean and sort the raw soybeans. This removes impurities such as stones, dust, and damaged seeds. According to a study conducted in China, this step alone can reduce impurities by up to 95%, significantly improving the overall quality of the oil.

Dehulling is the process of removing the outer shell of the soybean. This step increases the surface area for more efficient oil extraction. In a case study from a large-scale plant in Brazil, dehulling increased the oil yield by 7% compared to non-dehulled beans.

After dehulling, the soybeans are crushed and flaked into thin layers. This allows for more effective oil expression during the next phase. The flaking process also helps to preserve the natural nutrients in the oil.

Oil extraction is typically done using either mechanical pressing or solvent extraction. Mechanical pressing is preferred in some markets due to its natural and chemical-free nature. According to data from the United States Department of Agriculture (USDA), mechanical extraction can yield about 80% of the available oil, while solvent extraction can reach up to 95%.

One of the major advantages of a multi-step production system is its flexibility. Whether you need high-purity oil for the food industry or refined oil for biodiesel applications, a modern soybean oil plant can be customized to meet your specific requirements. For instance, some plants offer cold-pressed oil for premium markets, while others focus on high-volume production for industrial use.

With the ability to adjust parameters such as temperature, pressure, and processing time, manufacturers can ensure their products align with international standards like ISO 22000 or HACCP. This not only enhances customer trust but also opens up new export opportunities.

Investing in a multi-step soybean oil production system offers long-term benefits. It improves oil yield, reduces waste, and ensures consistent quality—key factors that global buyers prioritize. Additionally, the ability to customize the process means you can meet the evolving demands of different markets without compromising on efficiency or performance.

If you're looking for a reliable and scalable solution for soybean oil production, our state-of-the-art facilities are designed to deliver exceptional results. Whether you’re a small processor or a large manufacturer, we can tailor our technology to fit your needs.