For global buyers looking to source high-quality soybean oil, understanding the production process is essential. Many procurement professionals are unaware of how each step in the soybean oil extraction process contributes to both yield and quality. This article reveals the secrets behind efficient soybean oil production and highlights why choosing a reliable manufacturer can make all the difference.

The first critical step in soybean oil production is cleaning. Raw soybeans often contain impurities such as dirt, stones, and foreign materials. Advanced sorting systems ensure that only clean, high-quality beans enter the next stage. According to industry data, proper cleaning can increase oil yield by up to 5% and reduce mechanical wear on equipment.

Dehulling removes the outer shell of the soybean, which is rich in fiber but low in oil content. This step significantly improves oil extraction efficiency. In a case study from a leading soybean oil plant in China, dehulling increased oil yield by 8% compared to non-dehulled processing. The result is not only higher output but also better oil clarity and stability.

After dehulling, the soybeans are crushed into flakes. This increases the surface area, making it easier for the oil to be extracted. Modern crushing systems use precise temperature and pressure controls to maintain the integrity of the soybean’s natural oils. A typical flake thickness of 0.3–0.5 mm ensures optimal oil flow during pressing.

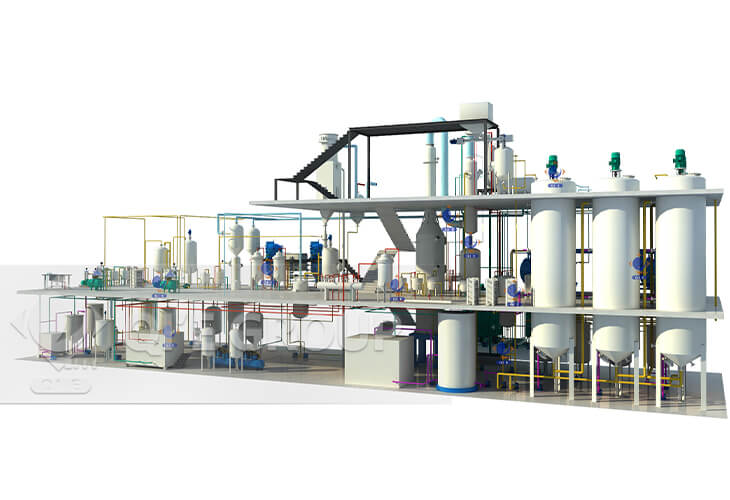

There are two primary methods for extracting oil: mechanical pressing and solvent extraction. Mechanical pressing is ideal for small-scale operations and produces cold-pressed oil with minimal chemical impact. For large-scale production, solvent extraction using hexane achieves the highest oil yield—up to 98% of available oil. Many manufacturers now integrate both methods to meet diverse customer needs.

| Process Step | Oil Yield (%) | Quality Impact |

|---|---|---|

| Raw Soybeans | 60–70 | High moisture, lower purity |

| Dehulled & Flaked | 75–85 | Improved clarity, higher purity |

| Pressing | 80–88 | Minimal chemical changes |

| Solvent Extraction | 95–98 | High yield, requires refining |

Refining is the final step that removes impurities, free fatty acids, and odors. It involves degumming, neutralization, bleaching, and deodorization. High-quality refineries use advanced filtration and temperature control to preserve the nutritional value of the oil while ensuring a long shelf life. A well-refined soybean oil can last up to 18 months without rancidity.

Choosing a manufacturer with a proven multi-step production process ensures consistent quality, higher yields, and compliance with international standards. Our company offers customizable solutions, including cold-pressing, solvent extraction, and full refining options, to meet your specific requirements. Whether you need bulk supply or tailored packaging, we provide flexible and scalable services.

Are you ready to take your soybean oil sourcing to the next level? Connect with us today to explore our production capabilities and find the best solution for your business.